CSI Scintillator

Acuri technology is manufacturer for high resolution and high performance x-ray scintillator. The CsI:Tl (cesium iodide) is available to deposit on any material for customer request.

Typical Application: Dental X-ray Imaging, Radiography and Oncology, Portal Imaging, Industrial NDT, In-line Inspection, Health and Safety, Mail, Parcel and Cargo Inspection, Baggage Check, Radiation Portal Monitoring, Spectroscopy and Electron Microscopy.

Fiber optic with x-ray scintillator

FOS (Fiber optic with x-ray scintillator) is x-ray imaging device provides high sensitivity and resolution than phosphor screen currently used. The FOS also allows real-time digital radiography when coupled to a CCD.

High quality digital image that far surpasses phosphor screen.

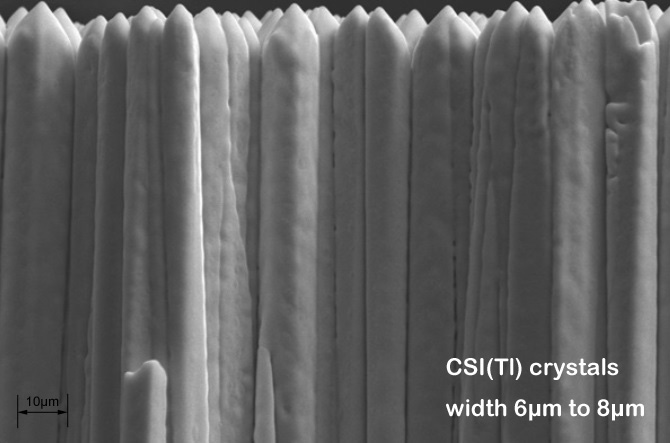

Thallium doped caesium iodide (CsI:Tl) is grown in a columnar ‘needle-like’ structure which provides excellent resolution, through reduced scattering, as each column of CsI acts as a light pipe channeling the visible light to the CMOS / CCD sensor below.

Acuri’s extensive experience and infrastructure provides volume manufacture of caesium iodide to exacting quality standards whatever your application, size and shape profile requirements.

Our production and application methods of CsI coatings, and indeed all our specialised coatings, brings two distinct advantages:

Superior output quality

Due to the slightly hydroscopic nature of CsI our coatings are encapsulated against moisture ingress. This encapsulation also provides a superior and robust finish to eliminate damage from transit and handling, maintaining image quality right to the edge of the scintillator, or sensor, area. We also offer an optional reflector / absorber layer to tailor and improve the output characteristics to better respond to your systems requirements.

Flexibility

Our CsI coatings can be applied to your systems exact size and profile shape requirements, on a wide range of substrates, for both small and large volume production runs.

Each order, and CsI based product or component, is indeed bespoke to each client.

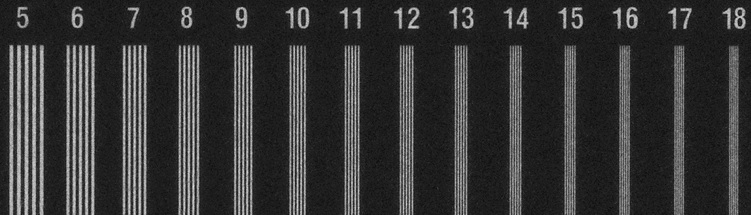

High Resolution : 18lp/mm

Phosphor screen is relatively thick since it contains materials other than luminescent materials. In contrast, the x-ray scintillator used in the FOS can be a thin coat since it consists only of luminescent materials. When x-rays strike and light is emitted from a luminescent material, the light tends to diffuse more in the phosphor screen since the distance to the film is longer. In the FOS, however, less light diffuses due to the thin layer and the fact that there isno space between the scintillator and the FOP. The smaller the light diffusion, the smaller the crosstalk, resulting in higher spatial resolution.

Aside from our standard product range, we also work in partnership with leading x-ray machine producers and manufacturers offering development and construction of customized scintillation products.

Please free contact us for large area scintillator, more detail product information and application.

Model | Scintillator | Substrate Thickness(mm) | Scintillator Thickness(μm) | Dimension(mm) |

FOS208 | CsI:Tl | 1.7 | 130 | 20.8 x 20.8 x 1.9 |

FOS269 | CsI:Tl | 1.7 | 130 | 26.9 x 26.9 x 1.9 |

FOS5060 | CsI:Tl | 1.8 | 130 | 50 x 60 x 2 |